The FloraPulse Microtensiometer works reliably and accurately when used correctly, but there are a few common occurrences that affect sensor performance. Here’s what could be going wrong when you see unexpected sensor readings. If you have any questions or concerns about your sensor’s performance, we are always available for technical support. Email admin@florapulse.com or call us at (530) 220-7668.

Incorrect Installation

Microtensiometers are generally easy to install, but of course if installed incorrectly, readings will be inaccurate. Common mistakes include not hammering the sleeve in far enough and failing to completely fill the sleeve with mating compound. These steps are critical to ensure a good sensor-xylem hydraulic connection and prevent infiltration of wounding exudates into the install site.

Fig 1. Microtensiometer that’s not installed deep enough. Not hammering the sleeve in far enough causes “gaps” between the sensor the tree.

Trunk is Too Small

The current Microtensiometer sensor is only recommend for use in trunks that are at least 2 inches (50 mm) in diameter. Installation into smaller trunks leads to two related problems:

- The wound will be too large relative to the trunk size, affecting the reading accuracy

- The sensor’s sleeve attachment is weak, which may cause the sensor to detach from the tree and show spurious readings

Incompatible Species

The microtensiometer has been validated in a large number of woody species, but some species still pose challenges. The wounding response of some trees, such as walnut and avocado, have excessive exudates that can flood the sensor. We recommend using microtensiometers only in species that have been validated – a full list is available in the installation manual.

External Damage to the Equipment

Orchard operations can damage the equipment if the wiring gets caught in machinery. Use caution when operating orchard machinery such as pesticide sprayers, pruning equipment, or harvest shakers. Likewise, pests such as rodents or bugs can chew on the wires and cause the sensor to break. If you suspect something is wrong with the readings, check on the equipment to see if its visibly damaged!

Fig 2. A Microtensiometer that was cut by orchard machinery.

Sensor Froze

Microtensiometers should be replaced at the beginning of each growing season. One reason for this is that the sensor can break if exposed to temperatures below freezing during the winter months. When storing the sensors, be sure to keep them out of extreme temperatures.

Wound Closure Over the Winter

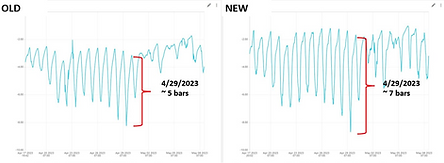

If a sensor has been left installed over the winter, it should be replaced or at least moved to a new installation site after leaf out. We have seen that in some species, such as almond, the installation site calluses over during the winter and causes the sensor readings to shrink. Installing the sensor into a new site generally eliminates this problem.

Fig 3. Comparison between sensor left over the winter (old) and a fresh install (new) in the same tree in Chico, CA. The fresh install reads about one bar wetter at predawn and a bar drier at midday then the older install.